The purpose of designing ventilation systems in poultry house is to maintain suitable air quality in the house and maintain the appropriate body temperature of poultry. This requires the air in the house to flow in the desired path and to meet the wind speeds required in extremely hot climates.

The essence of air flow is due to the existence of air pressure difference, that is, the air pressure at A is greater than that at B, and the air will flow from A to B. According to the power source of the ventilation system, the ventilation system of the poultry house can be divided into two types: natural ventilation and mechanical ventilation.

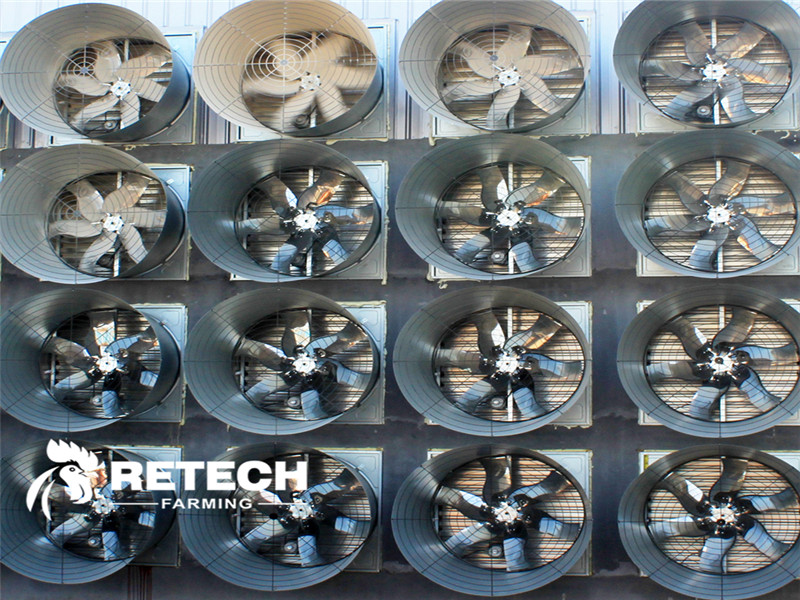

fans

1.Natural ventilation

The temperature difference on the surface caused by solar radiation, and then the air pressure difference is generated to realize the air flow.

The “natural wind” formed by the air pressure difference outside the poultry house is blown into the house through one side of the house and flows out from the other side or the other end; due to the thermal expansion and contraction of the air inside and outside the house, the air rises when heated. Generally speaking, the higher the temperature in the same area and the horizontal surface, the lower the air pressure.

2.Mechanical ventilation

Mechanical ventilation is powered by fans that cause indoor air movement. It is not limited by natural conditions, and it can send air to any designated place in the room through the fan, and can also discharge the air from any designated place in the room.

Mechanical ventilation can be divided into positive pressure ventilation and negative pressure ventilation. From the perspective of principle, positive pressure ventilation means that the air pressure inside the house is greater than the air pressure outside the house, and negative pressure ventilation means that the air pressure inside the house is lower than the air pressure outside the house.

1.Positive pressure ventilation.

Using a fan (such as a blower) to “squeeze” a large amount of air outside the house into the house through the air inlet, which will lead to an increase in the density of the air inside the house and its air pressure is higher than that outside the house, and then the dirty air will be discharged through the exhaust port. Natural “leakage” out of the house.

Positive pressure ventilation systems is often suitable for places with high air quality requirements, and it can be concentrated on the installation of equipment at the air inlet to pretreat the introduced air, such as purification, cooling or heating.

2.Negative pressure ventilation.

The air in the house is forced to be “pulled out” by the fan, the pressure in the house is also reduced and a certain negative pressure difference between the inside and outside of the house is formed (the air pressure inside the house is small), and the air outside the house naturally passes through the air inlet from the outside of the house. Being “sucked” into the house.

Negative pressure ventilation systems requires good airtightness of the poultry house, and the distribution of air inlets can be relatively scattered, but the exhaust fans are installed at one end.

brooding house

which is suitable for the setting, distribution and airflow direction of air inlets required for various ventilation modes (minimum, transition, longitudinal, etc.) of the breeding place. Therefore, the negative pressure ventilation system is the choice of the majority of breeding farms.